The carbide machining workshop specializes in the precision processing of hard alloys (tungsten carbide or cemented carbide), which are renowned for their exceptional hardness, wear resistance, and thermal stability. These materials are widely used in high-performance cutting tools, molds, wear-resistant components, and industrial applications requiring extreme durability.

Key Features:

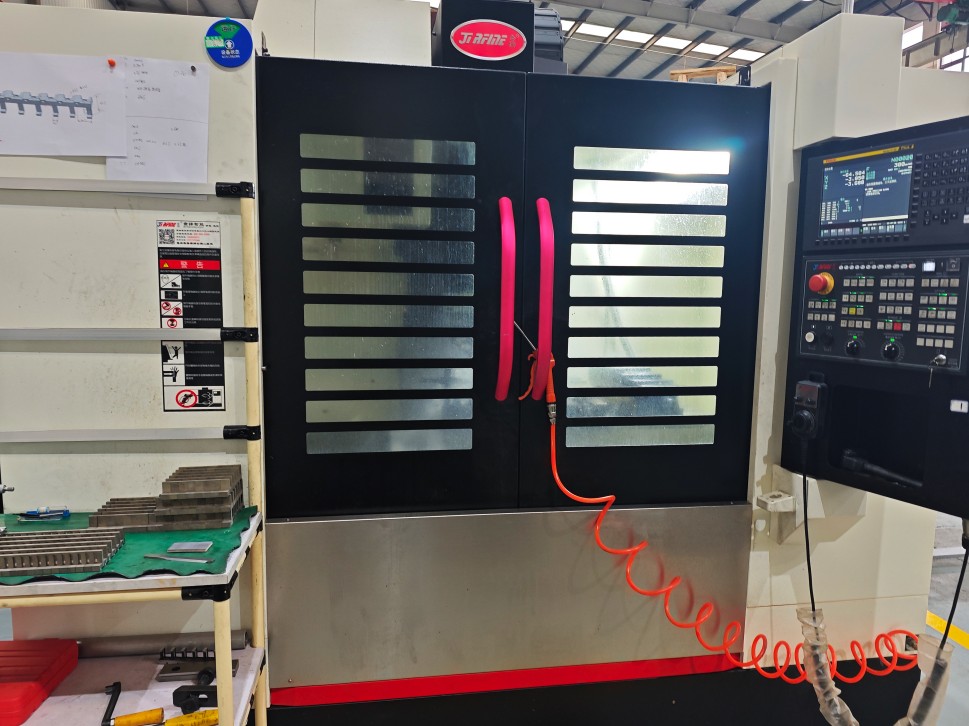

-CNC milling machines, lathes, and grinding machines tailored for hard alloy processing.

– Wire-cut EDM (Electrical Discharge Machining) and sinker EDM for intricate shapes.

-High-precision surface grinders and diamond-coated tooling for finishing.

– Precision machining of complex geometries with tight tolerances (±0.005 mm or better).

– Custom tool fabrication (e.g., inserts, drills, end mills) and wear parts.

– Heat treatment and surface coating (e.g., TiN, TiAlN) integration.

-State-of-the-art metrology tools: CMM (Coordinate Measuring Machine), roughness testers, and hardness testers.

– Compliance with ISO 9001 standards and strict process validation.

– Cutting tools for metalworking, mining, and oil/gas industries.

– Dies and molds for automotive, aerospace, and electronics manufacturing.

– Wear-resistant components for heavy machinery and industrial equipment.

Advantages:

– Expertise in handling ultra-hard materials with minimal tool wear.

– Rapid prototyping and small-to-large batch production.

-Collaborative engineering support for customized solutions.

Commitment:

Combining cutting-edge technology with skilled craftsmanship, the workshop delivers high-performance carbide components that meet the demanding requirements of modern industries.