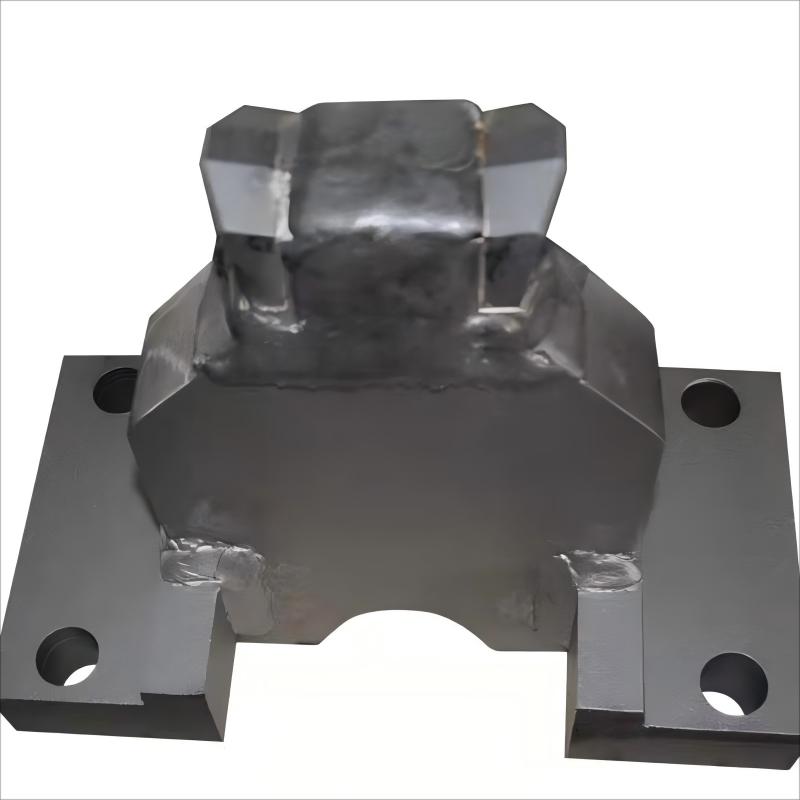

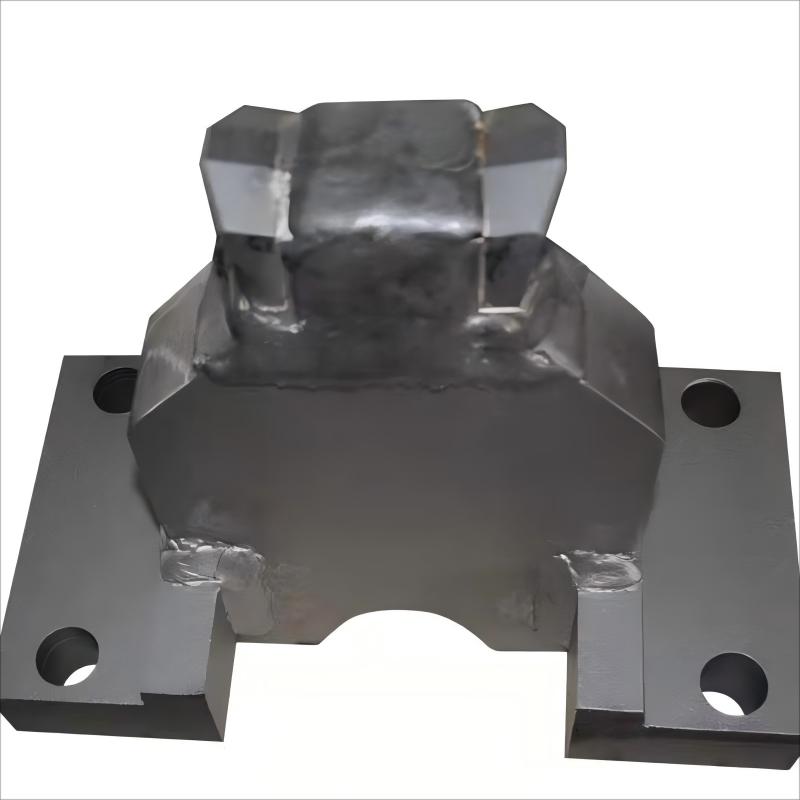

Chisel Cutter (commonly referred to as a Ripper Tooth or Chisel Bit) is a heavy-duty cutting tool designed for aggressive excavation in challenging geological conditions, such as fractured rock, boulder-filled soil, or highly abrasive mixed ground. Installed on tunnel boring machines (TBMs), excavators, or roadheaders, it leverages high-impact force to fracture and dislodge hard materials, ensuring efficient progress in demanding tunneling and mining operations.

Key Features:

1. Robust Material Composition

– Cutting Tip: Tungsten carbide (WC-Co) inserts or boron steel tips (HRC 60–65) for exceptional wear and impact resistance.

– Body: Forged from high-strength alloy steel (e.g., 30CrNiMo), heat-treated via quenching and tempering to balance hardness (HRC 45–50) and toughness.

– Anti-Corrosion Coating: Optional Zn-Ni plating or epoxy coating for wet or acidic environments.

2. Optimized Impact Geometry

– Chisel Edge Design: Sharp, wedge-shaped tip geometry concentrates force for efficient rock fracturing.

– Reinforced Base: Flared shoulders and ribbed structures prevent tip breakage under cyclic loading.

3. Modular & Replaceable

– Quick-Change Inserts: Bolt-on carbide tips or cartridge systems enable rapid replacement without welding.

– Adaptable Mounting: Compatible with standard TBM cutter blocks or hydraulic breaker attachments.

Applications:

– Tunnel Boring: Fracturing boulders and hard inclusions in EPB or Slurry TBMs.

– Mining: Breaking coal seams, shale, or iron ore in roadheaders and continuous miners.

– Demolition & Quarrying: Crushing reinforced concrete or asphalt in hydraulic breakers.

– Frozen Ground Excavation: Specialized carbide tips for Arctic pipeline or permafrost tunneling.

Performance Advantages:

1. High Impact Resistance

– Engineered to withstand 10⁶+ impact cycles without catastrophic failure.

2. Adaptability

– Interchangeable tips for varying ground conditions (e.g., conical tips for rock, flat tips for concrete).

3. Reduced Vibration

– Damped shank designs lower operator fatigue in handheld hydraulic breakers by 30%.

4. Cost Efficiency

– Replaceable tips extend tool life by 3× compared to monolithic designs.

Customization Options:

– Material Upgrades: Ultra-tough carbide grades (e.g., K20/K30) for extreme abrasion.

– Hybrid Designs: Chisel-pick combos for mixed ground (rock + clay).

– Ergonomic Handles: For manual rock-breaking tools in narrow tunnels.

Why Choose Our Chisel Cutters?

– Field-Proven Reliability: 20+ years of deployment in Himalayan tunneling projects.

– Rapid Prototyping: Custom tip geometries delivered in 7–10 working days.

– Sustainability: Closed-loop recycling program for tungsten carbide scrap.