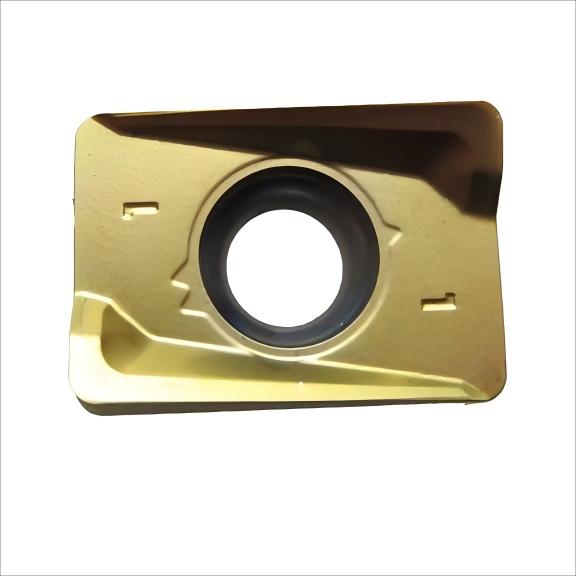

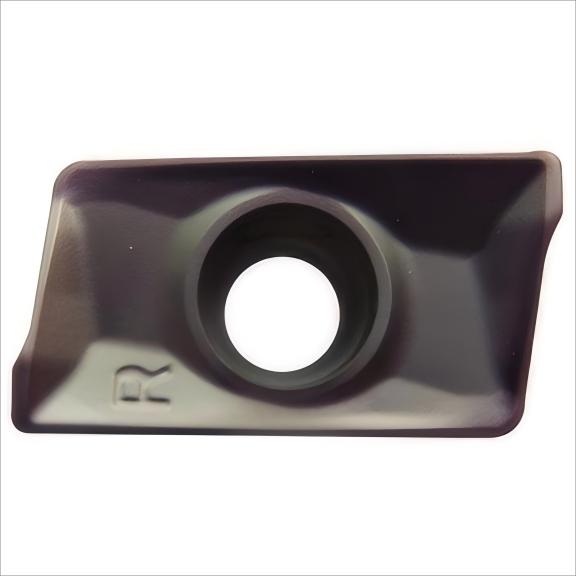

Milling inserts are precision-engineered, indexable cutting tools designed for high-efficiency machining in milling operations, including face milling, shoulder milling, slotting, and contouring. Constructed from high-grade tungsten carbide substrates and fortified with advanced coatings (e.g., TiAlN, AlTiN, or TiCN), these inserts deliver exceptional wear resistance, thermal stability, and edge toughness. Optimized for CNC milling machines, they enable aggressive material removal while maintaining precision across a broad spectrum of materials, such as steel, stainless steel, cast iron, aluminum, composites, and heat-resistant alloys

Key Features:

– Ultra-Durable Design:Tungsten carbide base combined with multilayer coatings ensures extended tool life in high-speed and heavy-load milling applications.

– Optimized Geometry: Multiple cutting-edge configurations (square, round, octagonal) and chipbreaker designs for efficient chip evacuation, reduced vibration, and superior surface finish.

– High Rigidity:Reinforced cutting edges and robust geometries withstand interrupted cuts and dynamic milling forces.

– Thermal Management:Advanced coatings dissipate heat effectively, minimizing thermal deformation and workpiece damage.

– Versatility:Suitable for roughing, semi-finishing, and finishing across vertical, horizontal, and gantry milling setups.

– ISO Standard Compliance: Common geometries (e.g., APKT, SEHT, RPMT, SPKN) ensure compatibility with global milling toolholders.

Benefits:

– Extended tool life and cost savings through multiple cutting edges per insert.

– Enhanced machining efficiency with higher feed rates and depth of cut.

– Superior surface quality and dimensional accuracy for critical tolerances.

– Reduced downtime with reliable performance in dry or coolant-assisted environments.

– Broad applicability in industries such as aerospace, automotive, mold-making, and energy.

Available Options:

– Multiple grades tailored for specific materials (ferrous, non-ferrous, hardened steels).

– Custom geometries, coatings, and edge preparations for specialized tasks (e.g., high-speed machining, titanium alloys).

Quality Assurance: Manufactured under strict ISO 9001 standards, ensuring consistent performance and repeatability.

Packaging: Individually packaged or bulk-supplied for high-volume production needs.

Elevate your milling productivity with Milling Inserts—engineered to tackle complex geometries, maximize material removal rates, and deliver precision in the most demanding industrial applications.