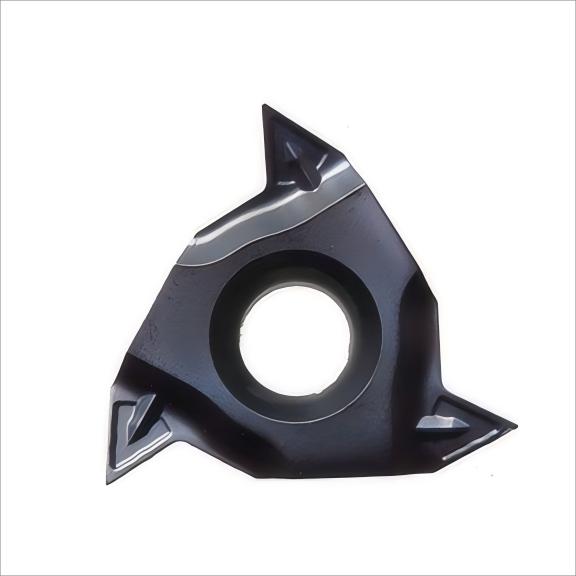

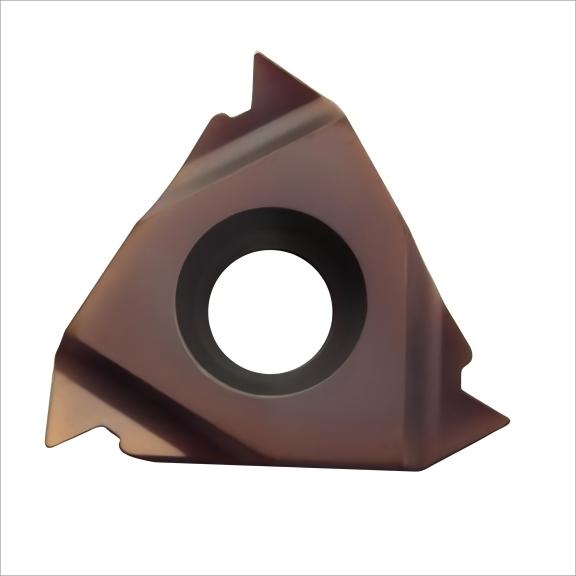

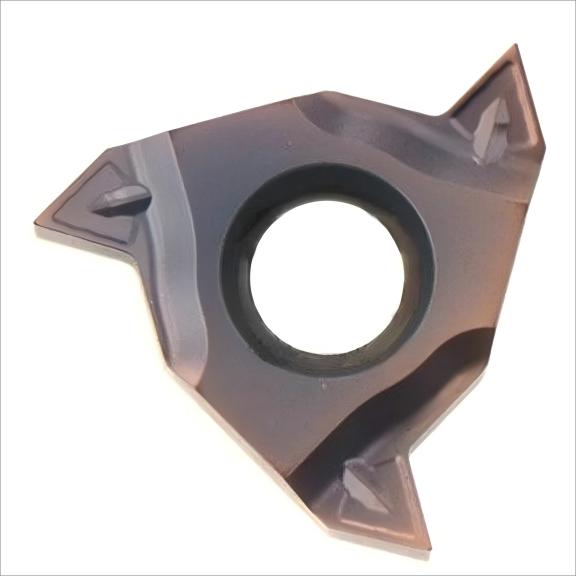

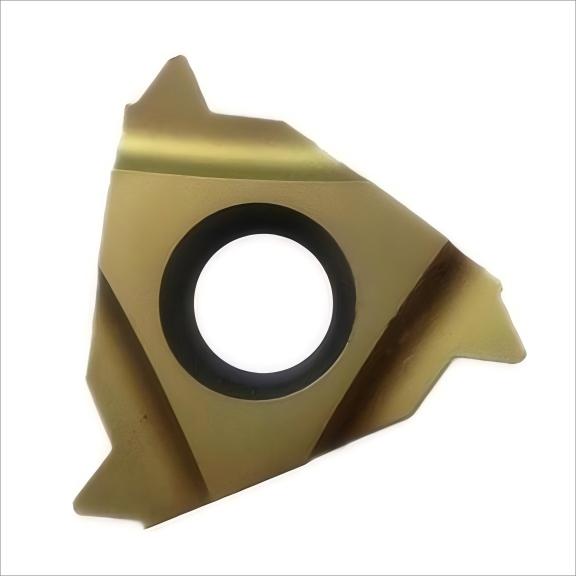

Threading inserts are precision-engineered cutting tools designed for creating accurate internal and external threads in turning operations. Crafted from high-grade tungsten carbide substrates and enhanced with specialized coatings (e.g., TiAlN, TiCN, or CVD layers), these inserts deliver exceptional wear resistance, thermal stability, and edge integrity for consistent thread quality across materials such as steel, stainless steel, cast iron, aluminum, and high-temperature alloys. Ideal for CNC lathes, they support metric, imperial, and custom thread profiles with unmatched precision and repeatability.

Key Features:

-Thread-Specific Geometry: Optimized rake angles, pitch accuracy, and cutting-edge profiles (e.g., 60° V-shape, trapezoidal) for ISO-compliant or custom thread forms.

-Reinforced Edge Design: Robust substrate and edge preparation to resist chipping and deformation during high-pressure threading.

-Advanced Coatings: Multilayer coatings minimize friction and heat buildup, extending tool life in dry or coolant-assisted machining.

-Multi-Tooth Efficiency: Multiple cutting edges per insert reduce replacement frequency and operational costs.

-Versatile Compatibility: Suitable for external, internal, single-point, and multi-start threading across a range of depths and diameters.

-ISO Standardization: Common geometries (e.g., 16ER, 16IR, 11ER) ensure seamless integration with global toolholder systems.

Benefits:

-High Precision: Achieve tight thread tolerances and superior surface finish for critical applications.

-Extended Tool Life: Coatings and carbide substrates withstand abrasive wear and high-temperature conditions.

-Increased Productivity: Reduced cycle times through optimized chip evacuation and stable cutting performance.

-Cost Efficiency: Multi-edge design lowers per-part tooling costs.

-Flexibility: Compatible with a wide range of materials and threading standards (e.g., UN, ACME, NPT).

Available Options:

-Material-Specific Grades: Tailored coatings and substrates for ferrous, non-ferrous, or hardened materials.

-Custom Profiles: Specialized geometries for unique thread forms or challenging applications (e.g., micro-threading, deep-hole threading).

-Coating Variants: Options for high-speed machining, dry cutting, or extreme thermal resistance.

Quality Assurance: Manufactured under stringent ISO 9001 standards, ensuring dimensional accuracy and repeatability for industrial reliability.

Packaging: Individually wrapped for protection or bulk-packed for high-volume production needs.

Elevate your threading operations with Threading Inserts—engineered to deliver flawless threads, reduce downtime, and maximize efficiency in automotive, aerospace, oil & gas, and precision engineering industries.